مقاومة التآكل سلسلة سبائك النحاس يتأثر بالعديد من العوامل الرئيسية ، بما في ذلك تكوين السبائك ، والظروف البيئية ، وخصائص المواد. فيما يلي نظرة عامة مفصلة على العوامل التي تؤثر على مقاومة التآكل لسبائك النحاس:

The elements added to copper to create alloys significantly impact corrosion resistance:

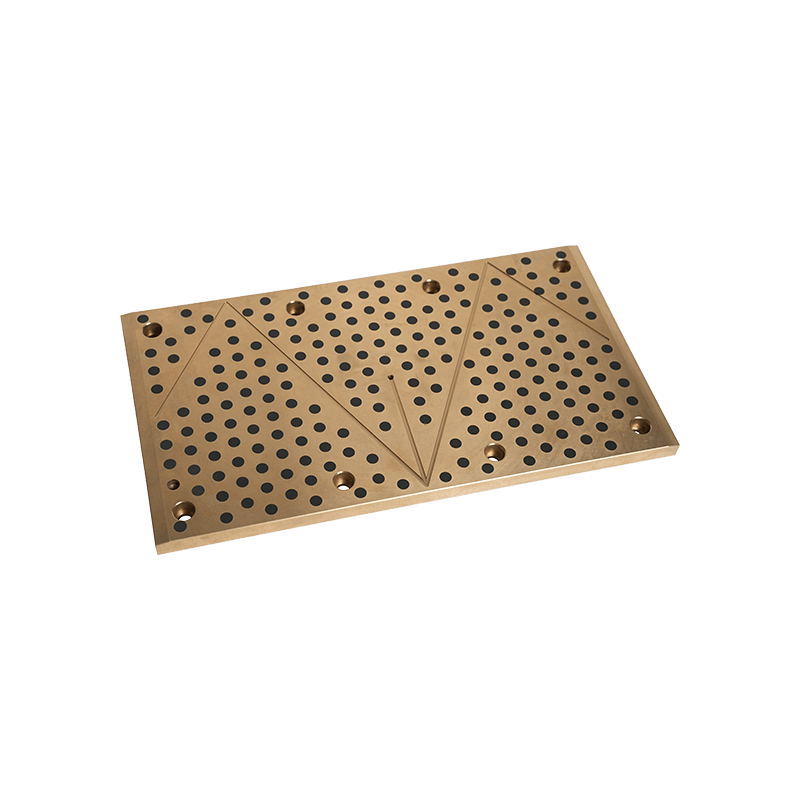

في النحاس ، تؤثر كمية الزنك على مقاومة التآكل. High zinc content can lead to dezincification, where zinc is leached out, leaving a porous copper structure.In bronze, tin improves resistance to corrosion, particularly in marine environments. Phosphor bronze, which also contains phosphorus, enhances wear resistance and corrosion resistance.Adding nickel (as in copper-nickel alloys) improves resistance to oxidation and corrosion, especially in seawater and harsh chemical environments.In aluminum bronze, aluminum enhances resistance to corrosion, including seawater and high-temperature environments.In leaded brass, lead improves machinability but can reduce مقاومة التآكل بشكل عام.

Copper alloys generally resist freshwater corrosion well, but some alloys might still experience issues like pitting or corrosion if exposed to aggressive conditions.Copper-nickel alloys and aluminum bronze perform exceptionally well in seawater due to their high resistance to saltwater corrosion.

تختلف مقاومة سبائك النحاس إلى البيئات الحمضية أو الأساسية. على سبيل المثال ، قد تتآكل النحاس بسرعة أكبر في الظروف الحمضية مقارنةً بسبائك البرونز أو النحاس نيكل. Exposure to chemicals like sulfur dioxide or chlorine can lead to accelerated corrosion. غالبًا ما تحتوي السبائك المصممة للاستخدام الصناعي على خصائص محددة للتعامل مع هذه الظروف.

High temperatures can affect the corrosion resistance of copper alloys.Can accelerate oxidation and degrade alloy properties.May not directly impact corrosion but can affect material performance and brittleness.

The microstructure of the alloy, including the distribution of phases and the presence of precipitates, influences its corrosion resistance. Uniform microstructures generally offer better performance.Finer grain structures can enhance corrosion resistance by reducing susceptibility to localized corrosion.

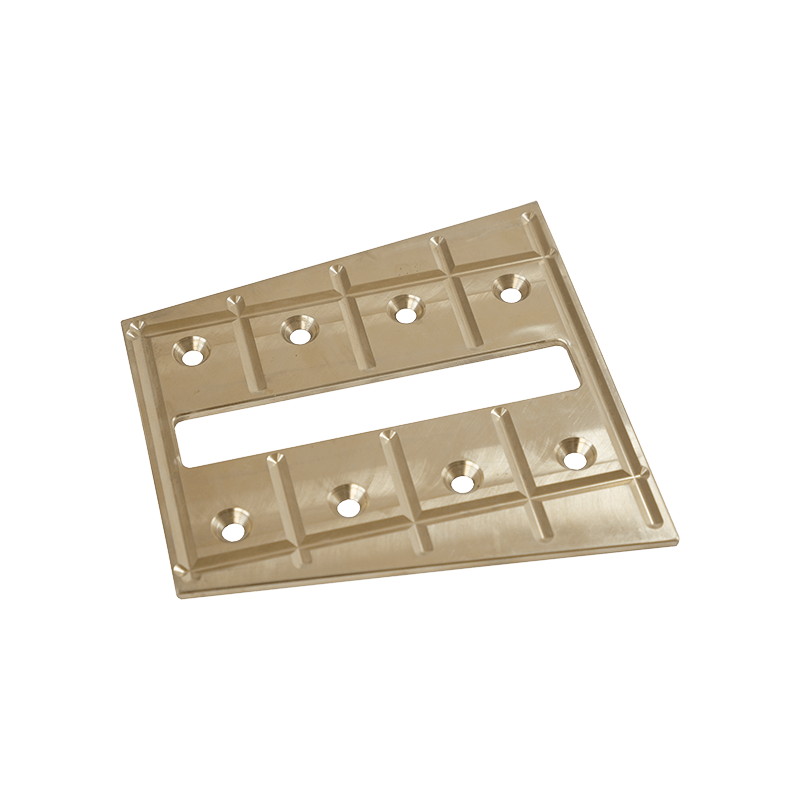

الأسطح الناعمة التي يتم صيانتها جيدًا أقل عرضة للتآكل من الأسطح الخشنة أو التالفة. Surface treatments and coatings can provide additional protection.Applying protective coatings or platings can shield copper alloys from aggressive environments, enhancing their overall corrosion resistance.

يمكن أن يؤثر الإجهاد أو السلالة الميكانيكية على مقاومة التآكل لسبائك النحاس. Stress-corrosion cracking can occur in some alloys if subjected to tensile stress in corrosive environments.Cold working or strain hardening can affect the alloy's resistance to corrosion, potentially making it more susceptible to stress-related failures.

The heat treatment process can influence the corrosion resistance of copper alloys by affecting their microstructure and phase composition.The method of fabrication can introduce impurities or defects that affect corrosion resistance. يساعد مراقبة الجودة المناسبة أثناء الإنتاج على ضمان أداء أفضل.

Regular maintenance, including cleaning and inspection, can prevent the buildup of corrosive agents and extend the life of copper alloys.Using appropriate protective measures, such as coatings or inhibitors, can further enhance corrosion resistance in specific applications.

العناصر المضافة إلى النحاس تؤثر بشكل كبير على مقاومة التآكل. Nickel and aluminum enhance resistance, while zinc and lead can have mixed effects.Exposure to different environments, including water, chemicals, and temperature variations, influences corrosion performance.The alloy's microstructure and surface treatment play crucial roles in its resistance to corrosion.Stress and strain can affect corrosion resistance, particularly in stressed or strained conditions.Proper fabrication and regular maintenance are essential for preserving corrosion المقاومة .

+0086-513-88690066

+0086-513-88690066